Gas Connections Are Not Like At Home!

|

If you make a trip covering many countries it is almost unavoidable that some adapters must be acquired locally. Learn more:

|

First Aid Kit

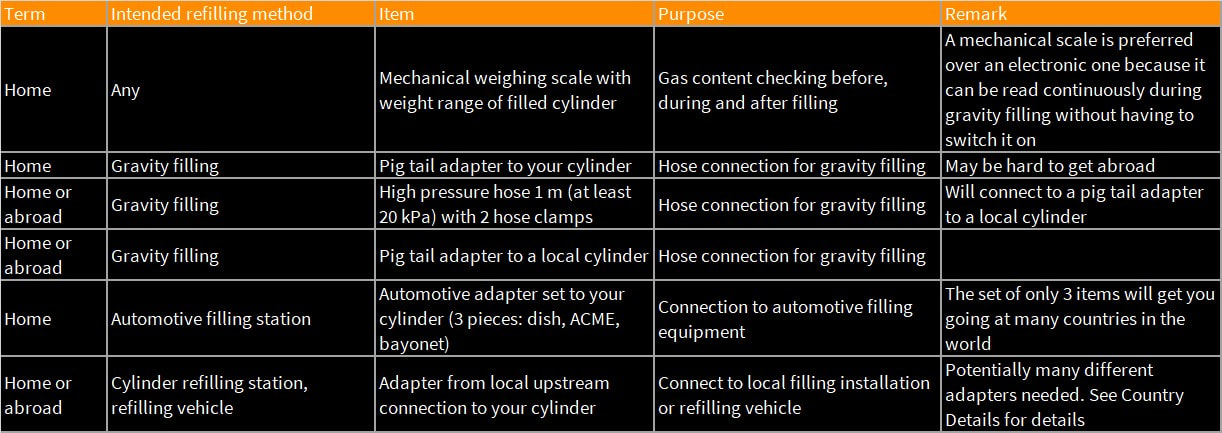

With some preparation before you set off it will be easier to replenish gas once you are on the road. The following items are recommended.

Steps For Safe Gravity Filling

|

Sometimes if no supplier of gas is available, but someones full tank is, you have no other option than gravity filling. Follow the steps below for safely filling from one cylinder into another:

|

Background Information About LPG, Gas Containers and Adapters

Refilling gas cylinders when traveling the world can be tough. Some (developing) countries don't use gas for cooking and heating, some will not allow filling of foreign cylinders. Furthermore for connection of propane/butane/LPG cylinders many different standards are applied and even within a single country five or more different standards can be in use. As on top of that the specification of commercially available adapters is often unclear or ambiguous it can be confusing for international travelers to determine what preparations are needed to ensure proper cylinder filling when abroad.

The purpose of this overview is to provide an overview of availability of propane/butane/LPG as well as applicable standards for connection of gas cylinders per country. The overview does not discuss installation of gas systems. More about that can be found in the Recommended Documents. Furthermore it does not discuss individual suppliers of gas. More about that can be found at iOverlander. Discussed are propane, butane and LPG (Liquefied Petroleum Gas). If the name of a standard in used wasn't known (yet) it been identified with X…

Please send any feedback to [email protected] or as a comment in Facebook on the group Cooking Gas Around the World.

The purpose of this overview is to provide an overview of availability of propane/butane/LPG as well as applicable standards for connection of gas cylinders per country. The overview does not discuss installation of gas systems. More about that can be found in the Recommended Documents. Furthermore it does not discuss individual suppliers of gas. More about that can be found at iOverlander. Discussed are propane, butane and LPG (Liquefied Petroleum Gas). If the name of a standard in used wasn't known (yet) it been identified with X…

Please send any feedback to [email protected] or as a comment in Facebook on the group Cooking Gas Around the World.

Propane, Butane and LPG, What Is the Difference?

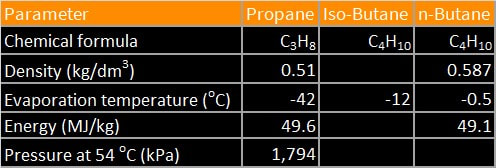

LPG (Liquefied Petroleum Gas) is a mixture of propane, (n-)butane and/or iso-butane. The ratio between the gases differs per country and supplier and can also be season dependent. Note the LPG is not LNG (Liquefied Natural Gas). Iso-Butane is more expensive to produce than n-Butane, therefore n-Butane is used more commonly. Iso-Butane has the same chemical formula as n-Butane, but its molecule form is different, giving it a lower evaporation temperature. Therefore it is sometimes used in camping canisters. Below are some important physical parameters. The density and energy values for LPG will be between propane and butane. Note that the evaporation temperature will not. When a mix of propane and butane is used most of the propane will evaporate first, because the vapor pressure is much higher. This continues until the propane in the mix is completely evaporated. The remaining gas is and behaves like butane.

Because a butane molecule has more carbon atoms than a propane molecule it needs more oxygen for full combustion. For this reason the optimal regulator pressure which determines the amount of flowing gas is higher for propane than for butane. In the UK 37 mbar is used for cooking with propane and 29 mbar for cooking with butane. However, most countries use a single system that is the best compromise with a regulator pressure of about 30 mbar.

Because a butane molecule has more carbon atoms than a propane molecule it needs more oxygen for full combustion. For this reason the optimal regulator pressure which determines the amount of flowing gas is higher for propane than for butane. In the UK 37 mbar is used for cooking with propane and 29 mbar for cooking with butane. However, most countries use a single system that is the best compromise with a regulator pressure of about 30 mbar.

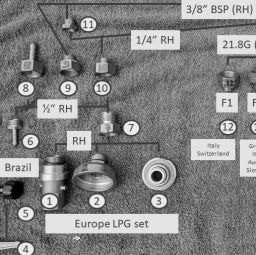

Comparing Standards

The standards described on this page can be found in the tool what connections are in use in a country. Because the sources of information were often inconsistent or incomplete the table contains most likely duplicates of standards. Furthermore it was sometimes necessary to use a working name for a standard, rather than a formal name such as Undetermined 06. To make the standards comparable critical parameters were provided when known:

- Outer thread diameter in mm (screw connection only)

- Thread density in mm (screw connection only)

- Connection INT (inside thread, female) or EXT (outside thread, male)

- Closing direction LH (turn counterclockwise to close) or RH (turn clockwise to close)

Safety

The most important risks when filling gas cylinders are leaks, overfilling and skin burning.

- Leaks: when the cylinder is filled no escaping gas should be heard or seen. Be aware that adapters with parallel threads are not always provided with rubber rings that are needed to prevent leaks. You may have to get them separately. Also keep PTFE (Teflon) tape at hand to seal a tapered connection;

- It is of vital importance that cylinders are not filled for more than 80% of their (volume) capacity. When the outside temperature increases the volume of the liquid inside the cylinder will increase as well. Risk of explosion exists if the liquid has no space to expand. The capacity of a cylinder is normally given in kg, because the amount of energy of gas is proportional to the weight, not to the volume. However, when a cylinder is filled the gas is sold by volume, not by weight. To ensure that you don't overfill assume 100% propane, because it has the lowest density and therefore the biggest volume for a given weight. Within measuring accuracies you can assume that 1 kg of propane has a volume of 2 dm3. For example a cylinder rated for 3 kg can safely be filled with 6 liters (6 dm3). It should have a volume capacity of at least 6 liters/80% = 7.5 liters. By consequence if you have not filled the cylinder with propane but with butane the gas weight will be about 3.5 kg (6 dm3 x 0.587 kg/dm3). A mixture propane and butane will be between 3 kg and 3.5 kg. Similarly if the cylinder that you want to fill is not empty assume 2 liters of liquid per kg;

- When liquefied gas evaporates the expansion causes it to cool down tremendously. A flow of evaporating gas may therefore cause serious skin burns.

Filling Methods

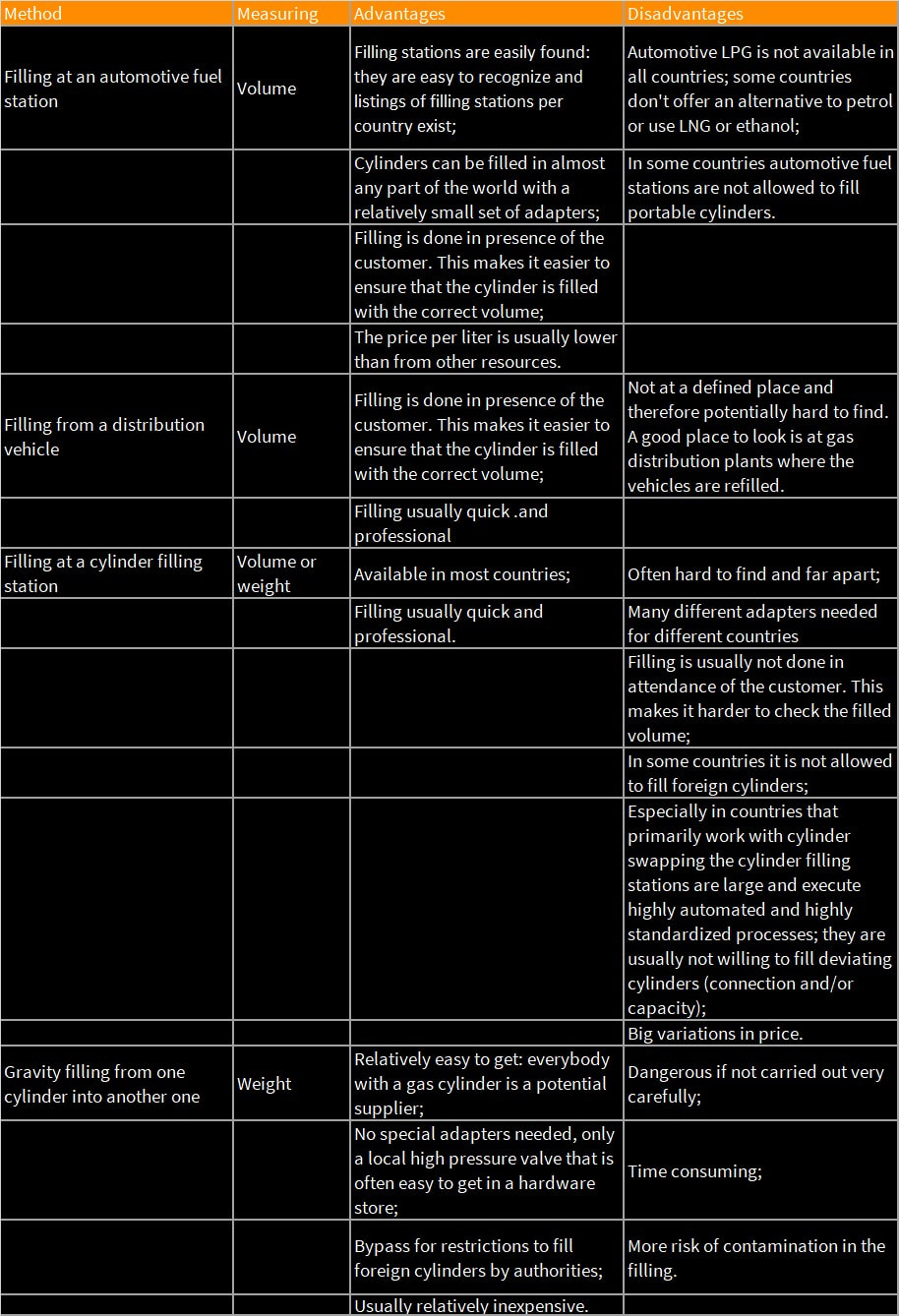

Four methods of filling exist: filling at an automotive fuel station, filling from a distribution vehicle (a car driving around to fill fixed tanks), filling at a cylinder filling station and gravity filling from one cylinder into another one. Measurement of the quantity of gas being filled is by volume or by weight. If the cylinder to be filled has no overfill protection this quantity must be calculated beforehand.

In the document the terms upstream (side of the cylinder) and downstream (side of the stove, heater, etc.) are used. These are valid in the situation of a filling station. Obviously downstream becomes upstream when gravity filling.

Bleeder Valves

|

A bleeder valve (fixed liquid level gauge) depicts the level of liquid in the tank when it is being filled. When the propane going into the tank reaches 80%, liquid will come out of the opened valve. This shows that the tank has reached its maximum filling capacity. The valve is connected to a dip tube that goes into the container. The dip tube is fixed and set at length equal to 80% liquid level tank capacity: the tip of the dip tube is at the level equal to the container being 80% full. The dip tube itself should always be located in the vapor space and never submerged in liquid. When a container is filled it is opened with a screw on the valve. Because the pressure in the container being filled is lowered by the escaping vapor the filling station doesn't need a pump to fill; the natural pressure is sufficient.

Practical consequence is that in countries where bleeders are common (such as Australia) containers without a bleeder only partially (1/3 or so) can be filled. |

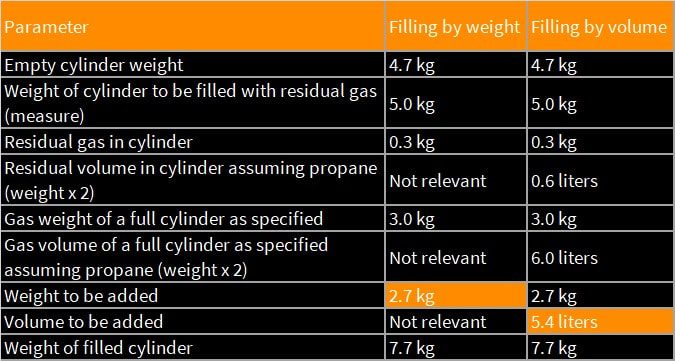

Quantity Calculation Example

|

Because a cylinder never shall be filled for more than 80% the required gas quantity must be calculated if the cylinder has no overfill protection. As propane has the lowest density always propane has to be assumed in the calculations. Below is an example of a calculation of the quantity of gas to be filled in case of weight as well as in case of volume measurement. The empty cylinder weight and gas filling weight are usually embossed on the cylinder foot or collar. In the example the empty cylinder is 4.7 kg, the gas weight of a full cylinder is 3 kg and the residual amount of gas before refilling is 0.3 kg. The cylinder must be weighed before and after filling.

|

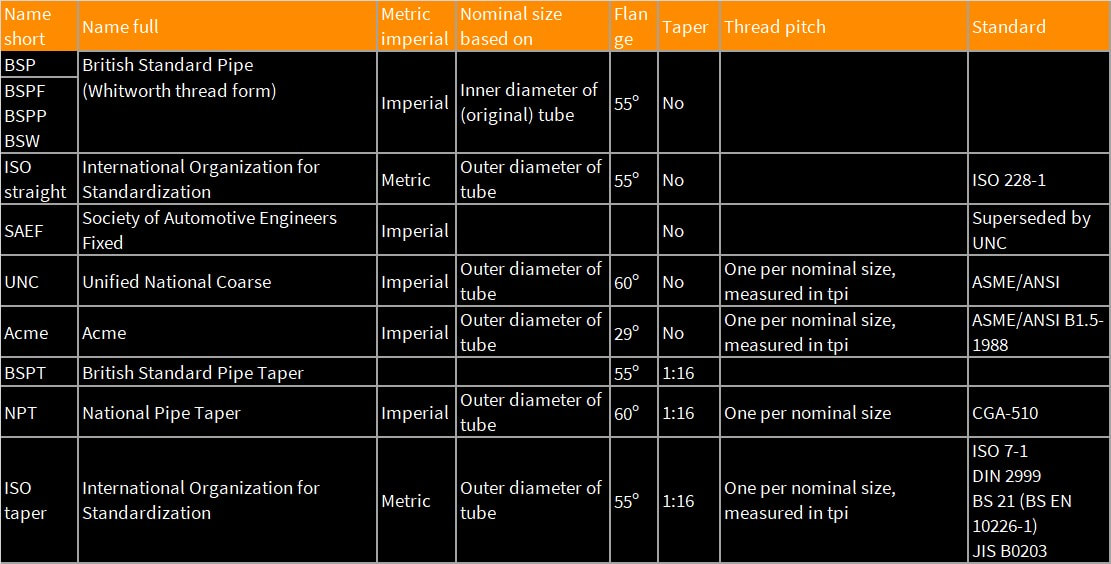

Thread Standards Used For Cylinder Valves

The first generally accepted standard was the Whitworth British Standard Pipe (BSP). Its size number was originally based on the inner diameter of a tube for which the thread was intended, but contemporary pipes tend to use thinner walls and thus have an inner diameter larger than this nominal size. The ISO and NPT standards were derived from BSP. Their nominal size is are based on the outer diameter of the tube and thus have a larger nominal size than the nominal size of the equivalent BSP.

Threads are either parallel or tapered. Tapered threads seal on the threads themselves. Parallel threads, if a leaktight fluid seal is required, seal with a gasket against the INT seat. An NPT EXT will fit into a BSPT INT or vice versa, but will not seal. Tapered EXT adapters have a taper thread that wedges into the INT adapter. They seal due to the "out of roundness principle" which means that the EXT stretches the INT fitting until there is so much force that the connection can hold pressure.

Threads are either parallel or tapered. Tapered threads seal on the threads themselves. Parallel threads, if a leaktight fluid seal is required, seal with a gasket against the INT seat. An NPT EXT will fit into a BSPT INT or vice versa, but will not seal. Tapered EXT adapters have a taper thread that wedges into the INT adapter. They seal due to the "out of roundness principle" which means that the EXT stretches the INT fitting until there is so much force that the connection can hold pressure.

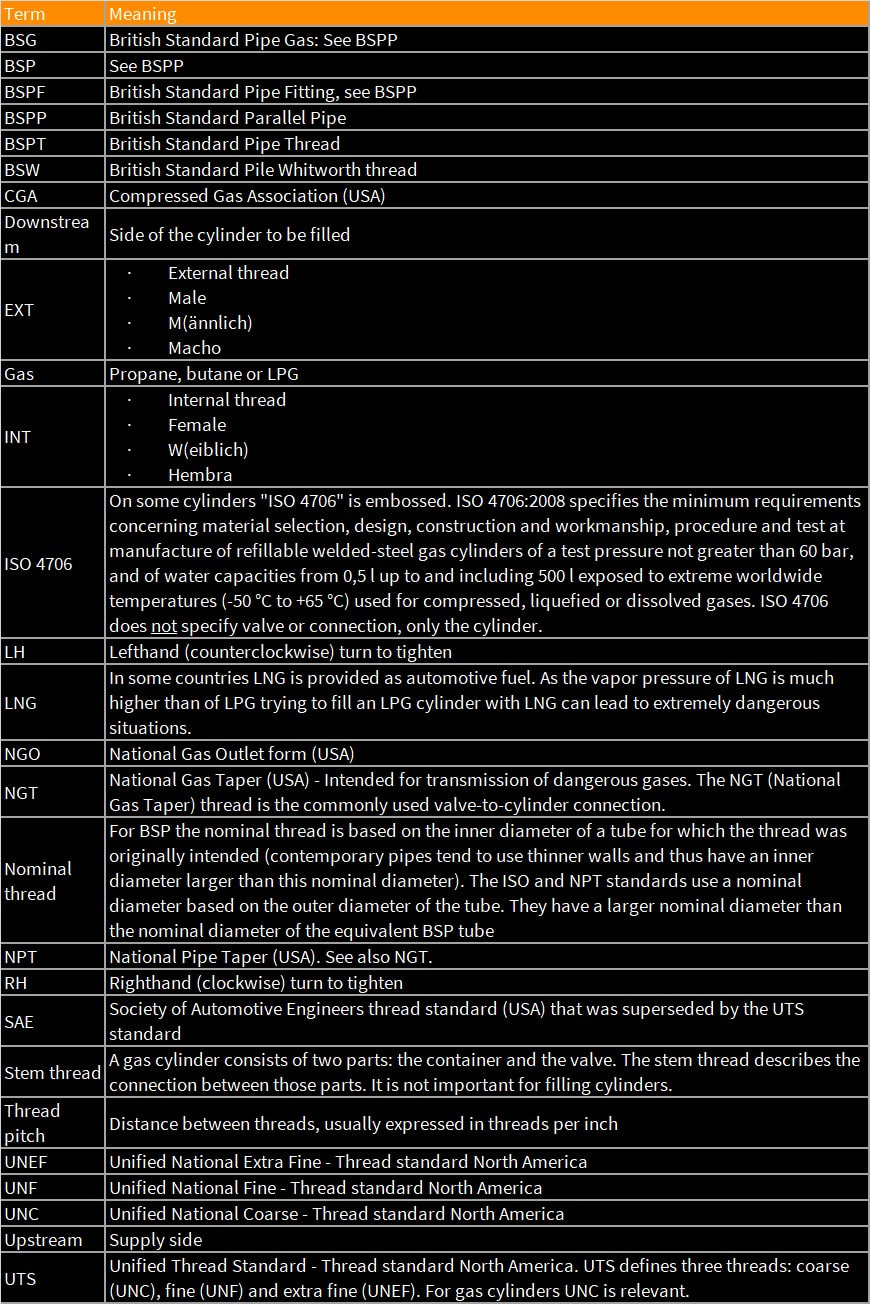

Definitions

Recommended Documents and Websites